Cranes

By utilizing the latest technology and continual improvement to our production processes, we offer unrivalled product quality when it comes to the production of cranes. We have a range of pre-engineered cranes to meet the requirements of almost all industrial applications. We offer a comprehensive range of cranes such as Wall Travelling Jib Cranes, Single/Double Girder Cranes, EX (Explosionproof) Cranes and Hoists, Cantilever Jib Cranes, Goliath Cranes, and Ladle Cranes.

Our cranes are manufactured in a state-of-the-art facility in a precision engineering environment. At ICON Engineering, we believe in a simple philosophy, which is to provide our clients with high-quality cranes to offer the best value for their money both in terms of initial capital investment and also lifetime ownership cost.

DESIGN CODE

ICON Cranes can be manufactured based on the customer requirements conforming to ANSI/NFPA, IEC, OSHA, NEC, IS, BS and other leading equivalent International standards.

The cranes & hoists can also be manufactured to also conform to certification along with the following specifications Cranes are designed by a team who has successfully delivered thousands of material handling equipments.

The team has expertise to conform to global design specifications including but not limited to the following:

BS 2573 IS 3177 IS 3938 DIN 15020 BS466 ASME B.30

Structural Material: The Structural Design strictly conforms to the design specifications and also ensures the girder deflection under 1/750 or 1/1000 as per the standard requested by the client. The material conforms to PMI and traceability procedures along with all intermediate inspections as applicable to ensure rejection of any defects in the material.

Product Portfolio

We are leading manufacturer and trader of quality Industrial Cranes and Material Handling Equipment. The equipment offered by us include:

- Single & Double Girder EOT Cranes

- Electric Monorail Hoists

- Electric Monorail Hoists for Curvature Tracks

- Crab Hoists

- Twin Hoist on Monorail Trolley

- EX (Explosionproof) Cranes & Hoists

- JIB Cranes

- Wall Travelling Catilever JIB Cranes

- Ladle Cranes

- Underslung Bridge Cranes

- Goliath Cranes

- Semi-Gantry Cranes

- Grab Buckets

- Winches

- ICON Gearboxes

- Grabbing Cranes

- Special Purpose Material Handling Equipment

In addition to these equipment we also offer Quality Structure Fabrication Services as per the exact require-ments of the client.

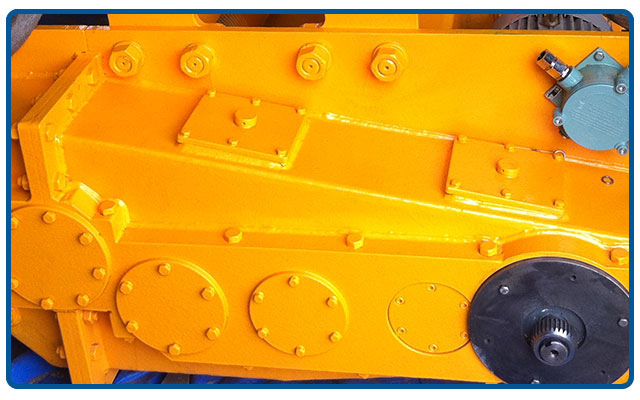

GEARBOX

- Lightweight gear units with silent running gears deliver the torque required.

- Precision gear units in light housings with case-hardened gears, high-grade surface treatment and permanent oil lubrication ensure high reliability and smooth running with a minimum of maintenance.

- The gear box casings are fabricated and stress relieved. All the pinions & gears are supported on Ball / Roller bearings. The pinion & gears are suitably hardened to take care of wear.

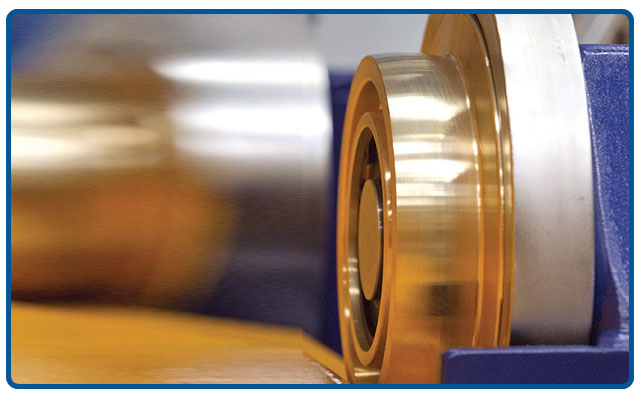

WHEEL ASSEMBLIES

- The wheels are manufactured from forged steel and hardened to min. 250 BHN hardness.

- The wheels are mounted on self aligning type roller bearings or on ball bearings.

- In case of Ex Equipments, the wheels are made of forged steel with HTB/PB collar for greater durability of the product.

ROPE DRUM

- The rope drum are fabricated from seamless pipe or rolled plates and are stress relived before machining.

- Rope drums are machined to receive the wire rope in single layer.

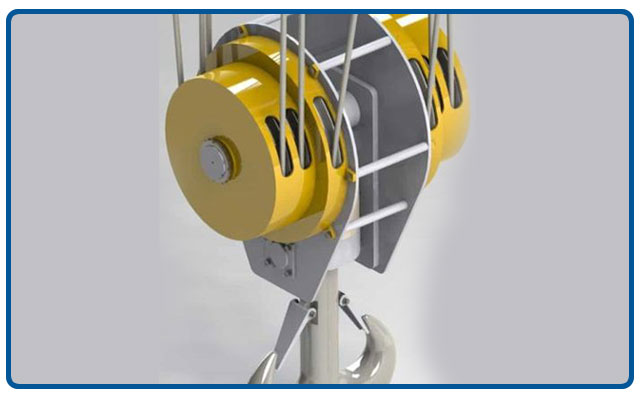

BOTTOM BLOCK

- The bottom blocks are equipped with double bearings for each suspension point to provide long lasting life to the unit.

- Long service life and high safety levels are outstanding features of the resilient steel rollers with machined rope grooves and annealed load hooks.

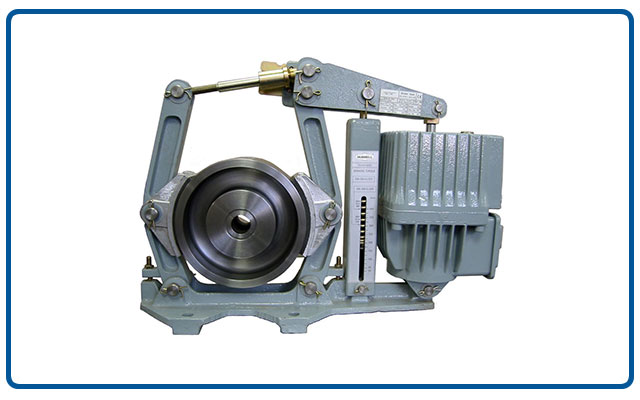

BRAKES

- All the motions are provided with crane duty electro hydraulic thruster operated brakes or EM DC Disc Brakes based on product application.

- The brake features automatic braking in the event of a power failure.

Comparison of FEM,HMI & CMAA Classifications Class 1 - Locations

| Hoist Classification | Corresponding Crane Class | Typical Application | |||

| FEM | HMI | ISO | CMAA | DIN 15018 & SIM | |

| 1cm | H1 | M2 | Class A | H1/B2 | Maintenance crane in machine house. Used only occasionally. |

| 1cm | H2 | M3 | Class B | H1/B2 | Light duty work shop crane, single shift operation, low average loads. Maximal load lifted occasionally. |

| 1Am | H3 | M4 | Class C | H2/B3 | Light/Medium duty work shop crane, single shift operation, medium average loads. Occasional lifting of max load. |

| 2m | H4 | M5 | Class D | H2/B3 | Medium/heavy duty work shop crane, 1 or 2 shift operation. Reular medium and heavy loads. |

| 3m | H4 | M6 | Class D | H2/B3 or H3/B4 | Heavy duty crane, 2 shift operation. Nominal load regularly lifted traverse or other deal loads below the hook. |

| 4m | H4 or H5 | M4 | Class D or Class E | H3/B4 or H4/B6 | Very heavy duty crane, 2-3 shift operation, grab or magnet below the hook. Regular heavy loads. |

PRODUCTS

CONTACT

- Office:

C2/Part 1, Kothari Compound No 3, 27 Acres, Tiku-ji-ni-wadi Rd, Thane 400.607

Work:

D4, Antariksh Logidrome, Kalyan-Sape Rd(Kalyan-Padgha Rd), Aamne 421302

- Tel: +91 9820165173 / +91 9820127996