Chain Hoists

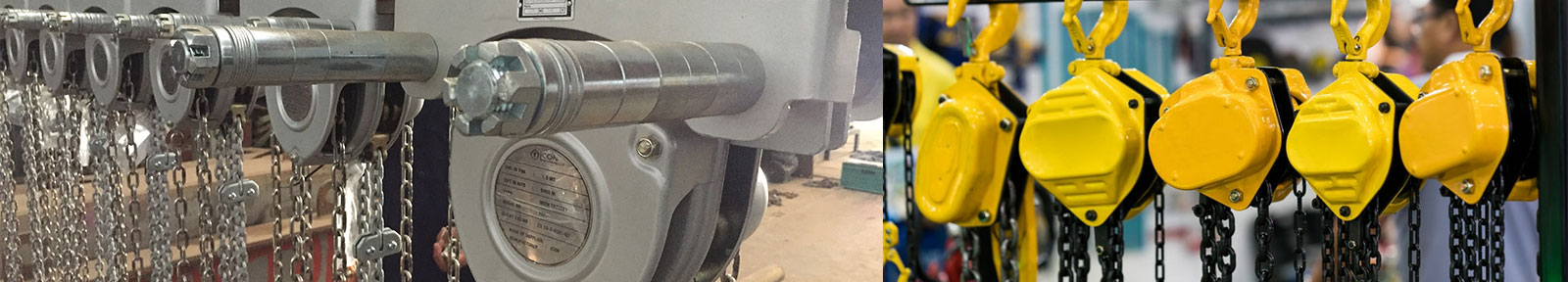

Manual Chain Hoist

ICON provides a range of Manual Chain Hoists, each with a set of features that will help you to select the right hoist for the task required. The Hoists are designed to meet the standard specifications and also with the host of options and accessories offered it helps in serving the demanding needs of applications.

Frames

ICON provides a range of Manual Chain Hoists, each with a set of features that will help you to select the right hoist for the task required. The Hoists are designed to meet the standard specifications and also with the host of options and accessories offered it helps in serving the demanding needs of applications.

Hooks

Hooks with safety latches, designed as standard. Made from forged alloy Steel and duly heat treated. Bottom Block Housing can also be provided with thrust bearing for easy rotary motion.

Load Chain Wheel

Steel is cast, heat treated, tested, accurately machined to suit calibrated load chain & bearings for free rotation, reducing effort for lifting.

Load Chain

Grade 80, alloy steel load chain as per Indian/international standard, electrically resistance welded, heat treated in induction furnace, calibrated and tested. Chains are manufactured to provide toughness, resistance to wear and corrosion.

Gears

Highly efficient, compact and hard-wearing gears made from alloy steel, precisely machined and case hardened for assured long life.

Bearings

To enhance mechanical efficiency, load wheel is mounted on sealed roller bearings fixed in frames. Additional bearings are also placed on gear cover to align the driving shaft and pinions.

Brake Mechanism

Precision self-actuating screw disc type mechanical brake engages instantly, outstanding stopping power and safety for high performance with rated capacity. Brake Disc Asbestos free long lasting, low wear and more griping ability.

Brake Disc

Asbestos free long lasting, low wear and more griping ability.

Minimal Maintenance

Easily disassembled, requiring no special tools.

Conforms to ASME B30.16

SPARKPROOF

| Capacity(T) | MT | 1T | 2T | 3T | 5T | 7.5T | 10T |

| No. of falls | 1 | 2 | 1 | 2 | 3 | 4 | |

| Chain Size Dia. | mm | 8 | 8 | 12 | 12 | 12 | 12 |

| Running pull on hand chain | Kgs. | 26 | 28 | 55 | 49 | 50 | 61 |

| Weight at 3 metre lift (approx) Hook Susp. | Kgs. | 21 | 30 | 55 | 70 | 100 | 126 |

| Extra weight per additional Kgs. 2.9 4.3 4.8 8 11.2 14.4 meterlift (approx) | Kgs. | 2.9 | 4.3 | 4.8 | 8 | 11.2 | 14.4 |

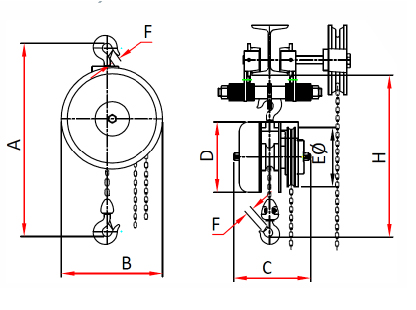

| Capacity(T) | A | B | C | D | EØ | F | Range of Beam Flange Length |

H Without Thrust bearing in Bottom Block |

H With Thrust bearing in Bottom Block |

| 1T | 460 | 210 | 180 | 210 | 195 | 31 | 64 - 305 | 550 | 580 |

| 2T | 560 | 240 | 180 | 210 | 195 | 37 | 88 – 305 | 665 | 760 |

| 3T | 750. | 300 | 225 | 275 | 720 | 42 | 100-305 | 925 | 950 |

| 5T | 810 | 320 | 225 | 275 | 270 | 51 | 114-305 | 950 | 1025 |

| 7.5T | 910 | 455 | 225 | 275 | 270 | 51 | 124-305 | 1025 | 1150 |

| 10T | 990 | 515 | 225 | 275 | 270 | 75 | 136-305 | 1120 | 1240 |

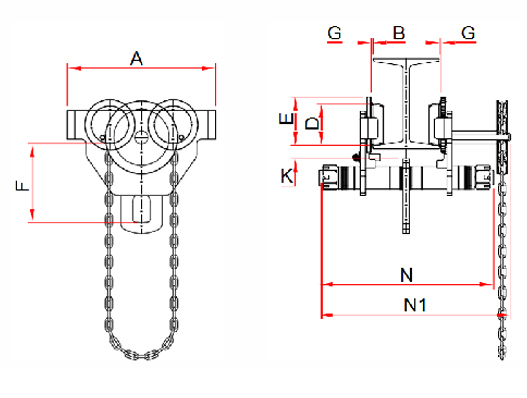

Manual Trolley

Frame:

- Built of plates are held tightly together by studs & nuts.

- Anti-Drop plate provided for protection.

Wheels:

- Graded casting Wheels are mounted on ball bearing. Geared Wheels are accurately machined using hobbing machinery.

- These Trolleys are suitable for running on I-beam flanges.

Hand chains:

- Electrically butt-welded. Accurately calibrated to easily fit into sprockets of Hand Chain Wheel, which in turn, is made out of graded casting as per Standard.

- The Curvature of the trolley can be supplied as per detailed drawing and specifications.

- The large diameter of Hand Wheel & higher tread diameter of wheels ensure less effort as well as smooth and faster movement horizontally.

| Type | Push Trolley Ptm | 1 | 2 | 3 | 4 | 10 | |

| Type | Gear trolley GTM | 1 | 2 | 3 | 4 | 10 | |

| Capacity | T | 1 | 2 | 3 | 4 | 10 | |

| Flange width B min.-max. | R2 | 64-203 | 88-203 | 100-203 | 114-203 | 124-203 | |

| R3 | 64-305 | 88-305 | 100-305 | 114-305 | 124-305 | ||

| Min. Curve radius | m | 0.9 | 1 | 1.2 | 1.3 | 1.7 | |

| A (Dimensions) | mm | 246 | 276 | 332 | 377 | 389 | |

| D | mm | 68 | 80 | 100 | 110 | 136 | |

| E | mm | 82 | 94 | 116 | 127 | 156 | |

| F | mm | 125 | 150 | 171 | 196 | 285 | |

| G | mm | 2 | 2 | 3 | 3 | 3 | |

| K | mm | 38 | 38 | 40 | 42 | 22 | |

| N (RANGE - R2) | mm | 311 | 327 | 343 | 355 | 403 | |

| N1 (RANGE - R2) | mm | 338 | 349 | 362 | 374 | 480 | |

| N (RANGE - R3) | mm | - | - | - | 430 | 450 | |

| N1 (RANGE - R3) | mm | - | - | - | 480 | 500 | |

| Weight PTM | kg | 10.5 | 17.5 | 27 | 41 | 48 | |

| Weight GTM | kg | 14.5 | 21.5 | 31 | 46 | 95 | |

| Hand Chain Size | mm x pitch | 5 x 25 | 5 x 25 | 5 x 25 | 5 x 25 | 5 x 25 | |

| Hand Chain | Zinc Plated | ||||||

| Trolley Wheel | Lining of HTB-2 on insert M.S./ En8 / En 9 / C.I. | ||||||

PRODUCTS

CONTACT

- Office:

C2/Part 1, Kothari Compound No 3, 27 Acres, Tiku-ji-ni-wadi Rd, Thane 400.607

Work:

D4, Antariksh Logidrome, Kalyan-Sape Rd(Kalyan-Padgha Rd), Aamne 421302

- Tel: +91 9820165173 / +91 9820127996