Chain Hoists

Electric Chain Hoists

Electric Chain Hoists by ICON Engineering can be used for standard to heavy-duty applications. These are designed and manufactured in compliance with the standards. Each Hoist is thoroughly tested and inspected before the shipment is delivered.

ICON specializes in the design engineering of Offshore duty Electric hoists in Hazardous environments. ICON hoists have been installed and commissioned at major international OIL & Gas platforms located at sea. We have the expertise required to design ultra-low headroom hoists, hoists with special turning radius and hoists with non-standard requirements.

We have successfully delivered hoists with above mentioned critical requirements to major international Oil & Gas players.

Electric Chain Hoists by ICON are available for standard duty to heavy duty applications. These are designed and all the specifications are as per standard. ICON electric chain hoists have many standard features traditionally known as optional on most electric chain hoists by other manufactures.

An Electric Chain Hoist must be designed to integrate into a system of choice. These include Overhead Bridge Cranes, construction Bridge Crane Kits, Rail Systems, to a standalone unit on a Jib Crane or Gantry Crane. Trolleys must provide smooth movement of load and create low resistance movement of the 'I' beam girders.

In a stationary installation, with push trolleys or electric trolleys, ICON Electric Chain Hoists prove to be extremely useful and user‐friendly. The advantages include very low headroom requirement for optimum space utilization, a standard precision lifting speed for sensitive lifting and lowering operations and brake linings with a long service life. The new generation of ICON's Electric Chain Hoists feature a fresh ergonomic design and a technically sound product. The motor and the gear unit are of modular design, allowing us to produce a wide variety of versions and ensuring that the overall design of the hoist is compact.

LONGER SERVICE LIFE

- Heavy duty DC brake is designed for a long service life.

- Lifetime grease-lubricated Gear Box and helical gearing ensures better wear and smooth operation. Heavy duty rated motors.

Each hoist is thoroughly inspected and tested to over 125% of rated load prior to shipment

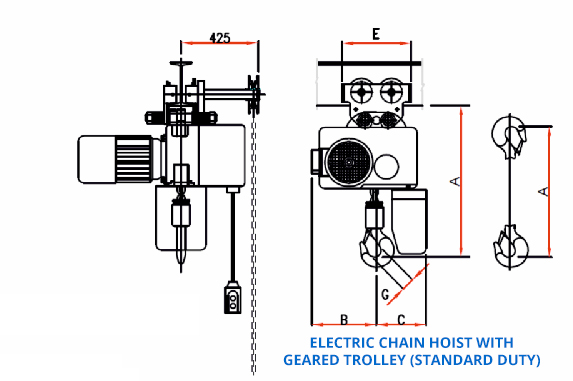

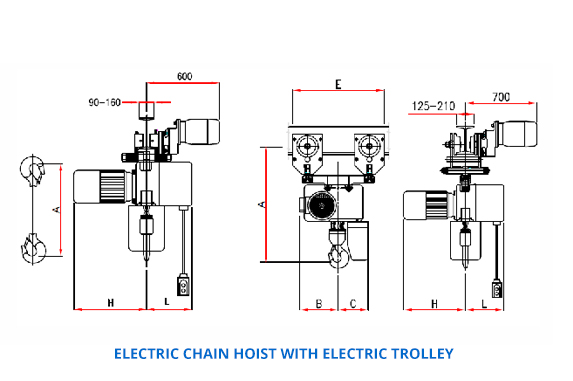

STANDARD DUTY

| Type | Standard Duty | ||||||

| Capacity (Kgs.) | 250 | 500 | 1000 | 2000 | 2500 | 3000 | 5000 |

| FEM Duty | 3M | 2M | 2M | 2M | 2M | 2M | 2M |

| ISO Duty | M6 | M5 | M5 | M5 | M5 | M5 | M5 |

| Lifting Speed (mpm) | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Chain Dia. (mm) | 4 | 6 | 7 | 10 | 10 | 10 | 10 |

| No. of Fall | 1 | 1 | 1 | 1 | 1 | 2 | 2 |

| Motor Capacity (kW) | 0.25 | 0.55 | 0.9 | 1.84 | 2.2 | 3.5 | 4.5 |

| Motor RPM | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| ‘A’ (Headroom without Trolley) | 550 | 550 | 550 | 600 | 600 | 950 | 1000 |

| ‘A’ (Headroom with Trolley) | 560 | 560 | 560 | 625 | 625 | 870 | 1100 |

| B | 200 | 200 | 200 | 280 | 280 | 280 | 280 |

| C | 200 | 200 | 200 | 325 | 325 | 325 | 325 |

| E | 280 | 280 | 280 | 350 | 350 | 350 | 800 |

| G | 32 | 32 | 32 | 38 | 38 | 46 | 53 |

| H | 300 | 300 | 300 | 450 | 450 | 500 | 500 |

| L | 250 | 250 | 250 | 380 | 380 | 400 | 400 |

| Weight in kG without Trolley (3M Lift) | 30 | 40 | 55 | 90 | 90 | 125 | 170 |

| Weight in kG with Trolley (3M Lift) | 65 | 75 | 90 | 135 | 150 | 185 | 250 |

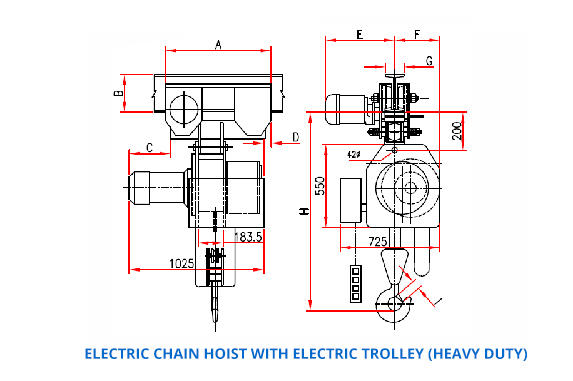

HEAVY DUTY

| Type | Heavy Duty | 1T | 2T | 3T | 5T | 7.5T |

| S.W.L. (Tonne) | MT | 2.5 | 5.0 | 7.5 | 10 | |

| No. of falls | mm | 1 | 2 | 3 | 4 | |

| Approx. weight | Fixed Suspension | Kg. | 328 | 381 | 402 | 427 |

| at 3 mts. Lift | with Electric Trolley | Kg. | 500 | 525 | 550 | 600 |

| with Geared Trolley | 376 | 451 | 553 | 578 | ||

| Extra weight per add. Mtr.lift (approx.) | Kg. | 3.3 | 6.6 | 9.9 | 13.2 | |

| Hoisting speed mts./min | MPM | 5.2 | 2.6 | 1.7 | 1.3 | |

| Travelling speed mts./min | MPM | 17 | 17 | 17 | 17 | |

| Hoisting motor | HP (kw) | 5(3.7) | 5(3.7) | 5(3.7) | 5(3.7) | |

| Travelling motor | HP (kw) | 0.25(0.18) | 0.5(0.37) | 0.75(0.55)x2 | 0.75 (0.55)x2 | |

| A | Electric trolley | mm | 730 | 730 | 730 | 930 |

| Geared trolley | mm | 496 | 496 | 616 | 616 | |

| B-min (ISMB) | Electric trolley | mm | 250 | 250 | 250 | 250 |

| Geared trolley | mm | 200 | 200 | 300 | 300 | |

| C | Electric trolley | mm | 345 | 345 | 345 | 164 |

| D | Electric trolley | mm | 60 | 60 | 60 | 72 |

| **E (min.-max.) | Electric trolley | mm | 425-468 | 425-468 | 425-468 | 425-468 |

| F (min.-max.) | Electric trolley | mm | 260-303 | 325-368 | 385-428 | 325-368 |

| G (min-max.) | Electric trolley | mm | 125-210 | 125-210 | 125-210 | 125-210 |

| Geared trolley | mm | 125-160 | 125-150 | 140-180 | 140-180 | |

| H (min.-max.) | Electric trolley | mm | 1050 | 1375 | 1500 | 1500 |

| Geared trolley | mm | 1175 | 1425 | 1550 | 1550 |

PRODUCTS

CONTACT

- Office:

C2/Part 1, Kothari Compound No 3, 27 Acres, Tiku-ji-ni-wadi Rd, Thane 400.607

Work:

D4, Antariksh Logidrome, Kalyan-Sape Rd(Kalyan-Padgha Rd), Aamne 421302

- Tel: +91 9820165173 / +91 9820127996