Wirerope Hoists

We, at ICON Engineering manufacture Wire Rope Hoist by using cutting edge design and technologies to offer exceptional performance, easy load handling, superior safety, and higher lifting speed. The design of the rope hoist facilitates simple, quick maintenance and repair of individual components, thereby minimizing downtime. Our wire rope hoists can be used for a variety of industrial applications.

DESIGN CODE

ICON Hoists can be manufactured based on the customer requirements conforming to ANSI/NFPA, IEC, OSHA, NEC, IS, BS and other leading equivalent International standards.

The cranes & hoists can also be manufactured to also conform to certification along with the following specifications

IS 3177 IS 3938 EN 60079 DIN EN 15020 + CE BS 4465

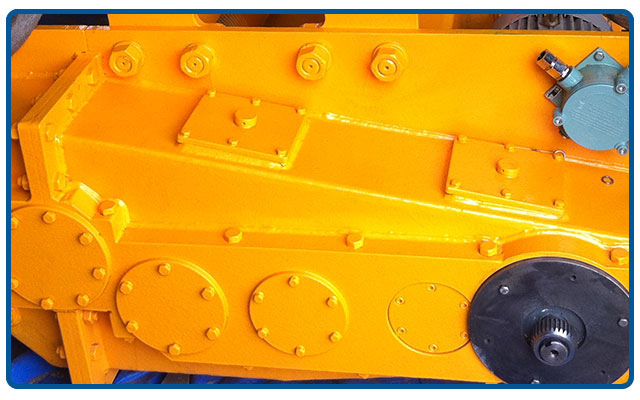

Gear Boxes

- Lightweight gear units with silent running gears deliver the torque required.

- Precision gear units in light housings with case-hardened gears, high-grade surface treatment and permanent oil lubrication ensure high reliability and smooth running with a minimum of maintenance.

- The gear box casings are fabricated and stress relieved. All the pinions & gears are supported on Ball / Roller bearings. The pinion & gears are suitably hardened to take care of wear.

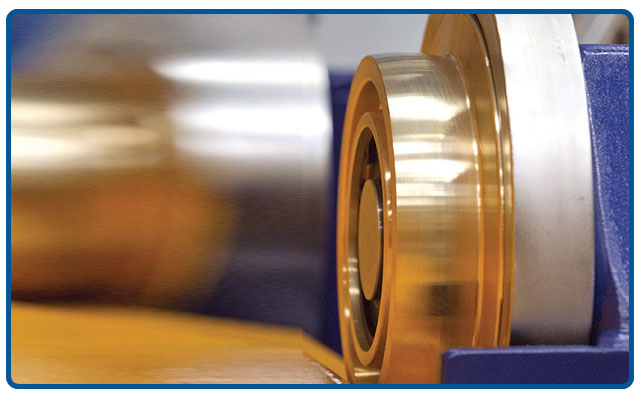

Wheel Assemblies

- The wheels are manufactured from forged steel and hardened to min. 250 BHN hardness.

- The wheels are mounted on self aligning type roller bearings or on ball bearings.

- In case of Ex Equipments, the wheels are made of forged steel with HTB/PB collar for greater durability of the product.

Rope Drum

- The rope drum are fabricated from seamless pipe or rolled plates and are stress relived before machining.

- Rope drums are machined to receive the wire rope in single layer.

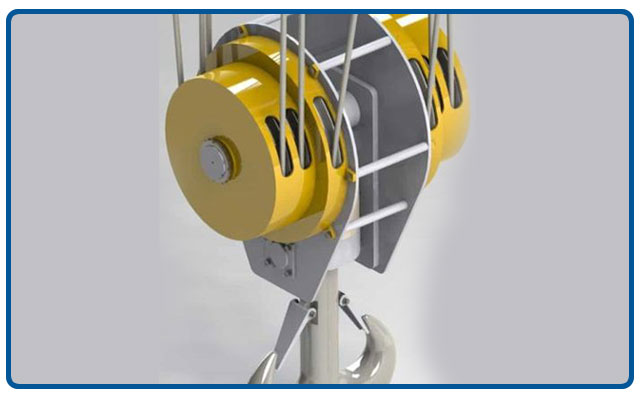

Bottom block

- The bottom blocks are equipped with double bearings for each suspension point to provide long lasting life to the unit.

- Long service life and high safety levels are outstanding features of the resilient steel rollers with machined rope grooves and annealed load hooks.

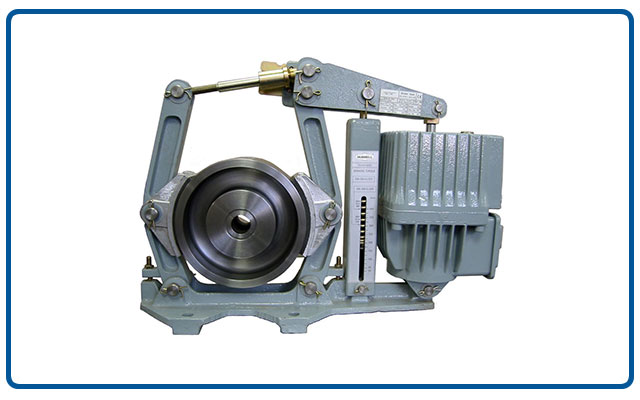

Brakes

- All the motions are provided with crane duty electro hydraulic thruster operated brakes or EM DC Disc Brakes based on product application.

- The electromagnetic brake features automatic braking in the event of a power failure.

Hoist motor

- Sturdy motors with cylindrical rotors and integrated fail-safe brakes are the power house of ICON wire rope hoists.

- ICON uses sturdy cylindrical rotor motors with integrated safety brakes.

- All the Motors are Crane Duty (S4), Squirrel cage type motors with 40 % CDF, 150 Starts/Hour Class B/F insulated in IEC frame size as per international standards

- Hoists are supplied as insulation class F, IP55 protected units motors. Stator subdivisions are optimized for higher electrical efficiency, smooth running and improved thermal capacity.

- Weather proof & Explosionproof motor configurations are also provided as an option.

Rope guide

- A resilient low-friction steel rope guide designed as an expanding ring provides positive guidance for the rope.

- The rope guide also reduces wear on the rope and rope drum.

- It is also easy to install, reducing maintenance requirements for the unit as a whole.

STANDARD HEADROOM HOISTS - 4*2 Configuration

| CAPACITY | HEIGHT OF LIFT HL -METERS | HOISTING SPEED 1. M/MIN | BEAM WIDTH SUITABILITY | C T SPEED | HOIST KW | CT KW | WEIGHT |

| 1000 | 4 | 3 | 150 – 300 | 15 | 0.75 | 0.18 | 550 |

| 2000 | 5 | 2.5 | 150 – 300 | 15 | 1.1 | 0.25 | 600 |

| 3000 | 6 | 1.5 | 150 – 300 | 15 | 1.1 | 0.37 | 750 |

| 5000 | 6 | 1.5 | 150 – 300 | 15 | 2.2 | 0.55 | 900 |

| 8000 | 6 | 1.5 | 150 – 300 | 15 | 3.7 | 0.75 | 950 |

| 10000 | 6 | 1.5 | 150 – 300 | 15 | 3.7 | 1.1 | 1400 |

| 12500 | 6 | 1.5 | 150 – 300 | 15 | 3.7 | 1.1 | 1700 |

| 15000 | 8 | 1.5 | 150 – 300 | 15 | 5.5 | 1.1 | 1800 |

| 20000 | 8 | 1.5 | 150 – 300 | 15 | 7.5 | 1.5 | 2200 |

| 25000 | 8 | 1.5 | 200 – 350 | 15 | 7.5 | 2.2 | 3200 |

| 30000 | 8 | 1.5 | 200 - 350 | 10 | 9.3 | 2.2 | 4500 |

| 40000 | 10 | 1.5 | 300 – 500 | 10 | 15 | 3.7 | 6000 |

| 50000 | 10 | 1.5 | 300 – 500 | 10 | 15 | 3.7 | 9000 |

STRAIGHT TRACK HOISTS

| A | B | H | L | h |

| 700 | 450 | 870 | 1100 | 150 |

| 700 | 500 | 900 | 1200 | 150 |

| 750 | 750 | 1100 | 1200 | 200 |

| 750 | 1000 | 1200 | 2000 | 250 |

| 750 | 1000 | 1300 | 2100 | 250 |

| 750 | 1000 | 1300 | 2100 | 250 |

| 900 | 1200 | 1500 | 2200 | 300 |

| 900 | 1200 | 1500 | 2200 | 300 |

| 1050 | 1300 | 1650 | 2400 | 350 |

| 1050 | 1300 | 1700 | 2400 | 350 |

| 1050 | 1300 | 1900 | 2400 | 350 |

| 1150 | 1400 | 2350 | 3000 | 450 |

| 1250 | 1500 | 2500 | 3000 | 450 |

ARTICULATED TRACK HOISTS

| A | B | H | L | h | C |

| 700 | 450 | 950 | 1100 | 150 | 2 |

| 700 | 500 | 1000 | 1200 | 150 | 2 |

| 750 | 750 | 1300 | 1200 | 200 | 2 |

| 750 | 1000 | 1400 | 2000 | 250 | 2 |

| 750 | 1000 | 1500 | 2100 | 250 | 2 |

| 750 | 1000 | 1500 | 2100 | 250 | 2 |

| 900 | 1200 | 1650 | 2200 | 300 | 2 |

| 900 | 1200 | 1650 | 2200 | 300 | 2 |

| 1050 | 1300 | 1650 | 2400 | 350 | 2.5 |

| 1050 | 1300 | 1900 | 2400 | 350 | 3 |

| 1050 | 1300 | 2000 | 2400 | 350 | 4 |

| 1150 | 1400 | 2750 | 3000 | 450 | 5 |

| 1250 | 1500 | 2850 | 3000 | 450 | 6 |

LOW HEADROOM HOISTS - 4*2 Configuration

| CAPACITY | HEIGHT OF LIFT HL - METERS | HOISTING SPEED 1.5 M/MIN | BEAM WIDTH SUITABILITY | C T SPEED | HOIST KW | CT KW | WEIGHT |

| 1000 | 4 | 3 | 150 - 300 | 15 | 0.75 | 0.18 | 550 |

| 2000 | 5 | 2.5 | 150 - 300 | 15 | 1.1 | 0.25 | 600 |

| 3000 | 6 | 1.5 | 150 – 300 | 15 | 1.1 | 0.37 | 750 |

| 5000 | 6 | 1.5 | 150 – 300 | 15 | 2.2 | 0.55 | 900 |

| 8000 | 6 | 1.5 | 150 – 300 | 15 | 3.7 | 0.75 | 950 |

| 10000 | 6 | 1.5 | 150 - 300 | 15 | 3.7 | 1.1 | 1400 |

| 12500 | 6 | 1.5 | 150 – 300 | 15 | 3.7 | 1.1 | 1700 |

| 15000 | 8 | 1.5 | 150 - 300 | 15 | 5.5 | 1.1 | 1800 |

STRAIGHT TRACK HOISTS

| A | B | H | L | h |

| 750 | 1100 | 650 | 1800 | 250 |

| 750 | 1100 | 650 | 1800 | 250 |

| 750 | 1100 | 650 | 1800 | 250 |

| 750 | 1100 | 650 | 1800 | 250 |

| 850 | 1150 | 1000 | 2000 | 250 |

| 850 | 1150 | 1000 | 2000 | 250 |

| 900 | 700 | 1200 | 1500 | 300 |

| 750 | 850 | 1200 | 1500 | 300 |

ARTICULATED TRACK HOISTS

| A | B | H | L | h | C |

| 750 | 1100 | 750 | 1800 | 250 | 2 |

| 750 | 1100 | 750 | 1800 | 250 | 2 |

| 750 | 1100 | 750 | 1800 | 250 | 2 |

| 750 | 1100 | 750 | 1900 | 250 | 2 |

| 850 | 1150 | 1100 | 2000 | 250 | 2 |

| 850 | 1150 | 1100 | 2000 | 250 | 2 |

| 900 | 700 | 1200 | 1500 | 300 | 2 |

| 750 | 850 | 1200 | 1500 | 300 | 2 |

STANDARD HEADROOM HOISTS - 4*1 Configuration

| CAPACITY | HEIGHT OF LIFT HL - METERS | HOISTING SPEED 1.5 M/MIN | BEAM WIDTH SUITABILITY | C T SPEED | HOIST KW | CT KW | WEIGHT |

| 1000 | 4 | 3 | 150 - 300 | 15 | 0.75 | 0.18 | 550 |

| 2000 | 5 | 2.5 | 150 - 300 | 15 | 1.1 | 0.25 | 600 |

| 3000 | 6 | 1.5 | 150 - 300 | 15 | 1.1 | 0.37 | 750 |

| 5000 | 6 | 1.5 | 150 - 300 | 15 | 2.2 | 0.55 | 900 |

| 8000 | 6 | 1.5 | 150 - 300 | 15 | 3.7 | 0.75 | 950 |

| 10000 | 6 | 1.5 | 150 - 300 | 15 | 3.7 | 1.1 | 1400 |

| 12500 | 6 | 1.5 | 150 - 300 | 15 | 3.7 | 1.1 | 1700 |

| 15000 | 8 | 1.5 | 150 - 300 | 15 | 5.5 | 1.1 | 1800 |

STRAIGHT TRACK HOISTS

| A | B | H | L | h |

| 600 | 700 | 900 | 1700 | 250 |

| 600 | 700 | 900 | 1700 | 250 |

| 850 | 700 | 900 | 1700 | 250 |

| 900 | 700 | 900 | 1700 | 250 |

| 900 | 700 | 1000 | 1800 | 300 |

| 900 | 700 | 1000 | 1800 | 300 |

| 1000 | 850 | 1150 | 1800 | 350 |

| 1000 | 900 | 1400 | 1800 | 350 |

ARTICULATED TRACK HOISTS

| A | B | H | L | h | C |

| 750 | 1100 | 800 | 1700 | 250 | 2 |

| 750 | 1100 | 800 | 1700 | 250 | 2 |

| 750 | 1100 | 800 | 1700 | 250 | 2 |

| 750 | 1100 | 800 | 1700 | 250 | 2 |

| 750 | 1100 | 900 | 1800 | 300 | 2 |

| 750 | 1100 | 900 | 1800 | 300 | 2 |

| 850 | 1150 | 1050 | 1800 | 350 | 2 |

| 850 | 1150 | 1250 | 1800 | 350 | 2 |

LOW HEADROOM HOISTS - 4*1 Configuration

| CAPACITY | HEIGHT OF LIFT HL - METERS | HOISTING SPEED 1.5 M/MIN | BEAM WIDTH SUITABILITY | C T SPEED | HOIST KW | CT KW | WEIGHT |

| 1000 | 4 | 3 | 150 - 300 | 15 | 0.75 | 0.18 | 550 |

| 2000 | 5 | 2.5 | 150 - 300 | 15 | 1.1 | 0.25 | 600 |

| 3000 | 6 | 1.5 | 150 - 300 | 15 | 1.1 | 0.37 | 750 |

| 5000 | 6 | 1.5 | 150 - 300 | 15 | 2.2 | 0.55 | 900 |

| 8000 | 6 | 1.5 | 150 - 300 | 15 | 3.7 | 0.75 | 950 |

| 10000 | 6 | 1.5 | 150 - 300 | 15 | 3.7 | 1.1 | 1400 |

| 12500 | 6 | 1.5 | 150 - 300 | 15 | 3.7 | 1.1 | 1700 |

| 15000 | 8 | 1.5 | 150 - 300 | 15 | 5.5 | 1.1 | 1800 |

STRAIGHT TRACK HOISTS

| A | B | H | L | h |

| 800 | 700 | 500 | 1150 | 250 |

| 850 | 950 | 600 | 1300 | 250 |

| 850 | 950 | 600 | 1300 | 250 |

| 850 | 950 | 600 | 1300 | 250 |

| 1000 | 1100 | 750 | 1650 | 300 |

| 1000 | 1100 | 750 | 1650 | 300 |

| 1250 | 1000 | 1200 | 1800 | 300 |

| 1250 | 1000 | 1200 | 1800 | 300 |

ARTICULATED TRACK HOISTS

| A | B | H | L | h | C |

| 800 | 700 | 550 | 1150 | 250 | 2 |

| 850 | 950 | 700 | 1300 | 250 | 2 |

| 850 | 950 | 700 | 1300 | 250 | 2 |

| 850 | 950 | 700 | 1300 | 250 | 2 |

| 1000 | 1100 | 850 | 1650 | 300 | 2 |

| 1000 | 1100 | 850 | 1650 | 300 | 2 |

| 1250 | 1000 | 1500 | 1800 | 300 | 2 |

| 1250 | 1000 | 1500 | 1800 | 300 | 2 |

PRODUCTS

CONTACT

- Office:

C2/Part 1, Kothari Compound No 3, 27 Acres, Tiku-ji-ni-wadi Rd, Thane 400.607

Work:

D4, Antariksh Logidrome, Kalyan-Sape Rd(Kalyan-Padgha Rd), Aamne 421302

- Tel: +91 9820165173 / +91 9820127996